Knurled Pins & Studs

Knurled Pins are similar to grooved pins that have serrations around the diameter. However, knurled pins feature many more serrations. They are press fit fasteners that, when compressed into a hole, extrude radial forces to hold the fastener in place.

- The best fastener for die casting and plastic application; superior fastening in the assembly of components which have thin cross sections and for formed sheet metal hinges

- Available with straight, helical or diamond knurling

- All knurled pins are special order

- Various diameters, lengths and end

configurations available - Style Choices: Straight, Diamond & Helical

Description

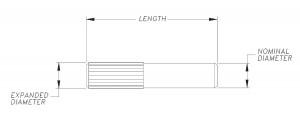

Knurled pins are similar to grooved pins because they have serration around the nominal diameter of the pin. The knurled pin differs from the grooved pin while there are many serrations on a knurled pin. Also, knurled pins are typically roll formed whereas grooved pins are swaged. A knurled section may have either a straight knurl, a helical knurl, or a diamond knurl configuration.

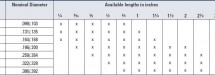

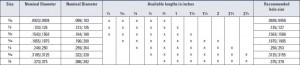

Knurled pins are available with nominal diameters from 3/32″ through 3/8″ and lengths from 3/16″ through 3″.

Function

The serrations on a knurled pin, when compressed by insertion into a hole, result in forces which hold the fastener in place. Radial forces are more evenly distributed around the diameter of a hole for knurled pins than for grooved pins. This is because a knurled pin has more points of contact with a hole than a grooved

pin. The teeth may broach the mating hole when the material is softer and more ductile than the pin material.

The amount of expansion is predicated on the knurl pitch. Coarse knurls provide greater expansion than fine knurls. A knurled pin should have a minimum of 15 teeth to allow proper feed and rolling capability. The number of teeth must be a whole number to allow for proper tracking and avoid slivering. The capability on expanded diameter tolerance is +/-.002. Call for assistance in determining proper knurl pitch for your applications.

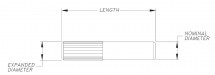

Dimensions

CAD Diagram

Success stories

SITUATION

A customer was looking for a way to fasten an aluminum extrusion to an aluminum end plate for use in a lighting

application.

SOLUTION

Driv-Lok’s ENGINOMICS® team designed and produced a fastener that combined two of our technologies- a Knurl on one end and a Barb-Lok on the other. This allowed the customer to easily install the plate onto the extrusion,

securely holding it in place while using only one type of fastener.The new fastener also eliminated the need for

expensive driving equipment, saving the customer money.

ADVANTAGES

- Two-way design resists pullout

- Increases speed of assembly

- Reduces boss fractures

- Eliminates expensive driving equipment